With the theme of developing environmentally friendly leather,

We manufacture a variety of new leathers

as well as conventional products.

With the theme of developing environmentally friendly leather,

We manufacture a variety of new leathers

as well as conventional products.

Because the process uses a lot of water and chemicals, we focus on using products

that are environmentally friendly, safe, and reliable.

Because the process uses a lot of water and chemicals, we focus on using products

that are environmentally friendly, safe, and reliable.

COMMITMENT TO TANNING

ECO-ZEOLITE TANNINGⓇ

What is ECO-ZEOLITE TANNINGⓇ?

By using zeolite, a harmless mineral, as a tanning agent instead of traditional tanning materials (vegetable tannins and chromium), we can create BIO-DEG LEATHERⓇ*1, a leather that returns to the natural environment. When buried in soil under certain conditions, it decomposes in about six months and returns to the earth as nutrients.

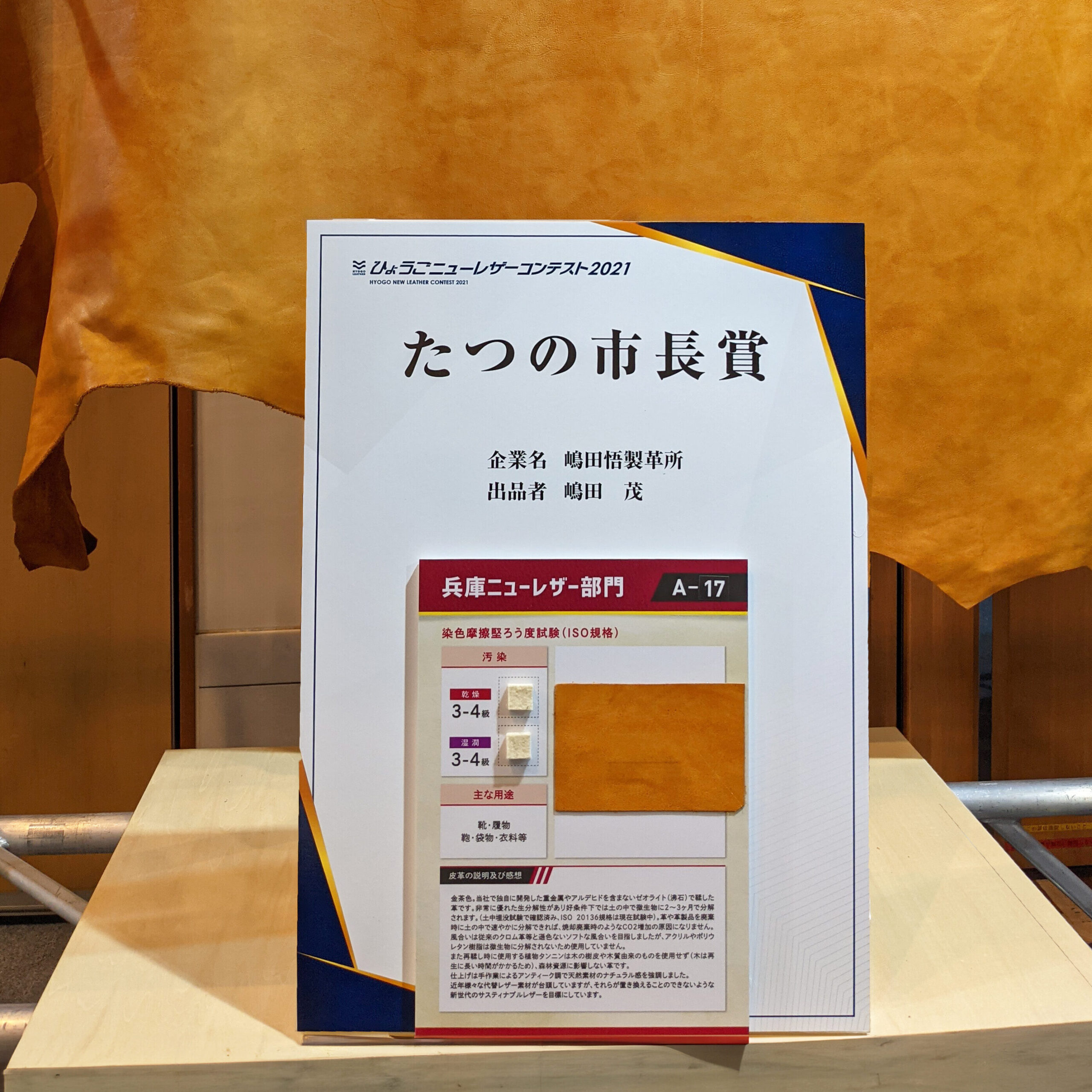

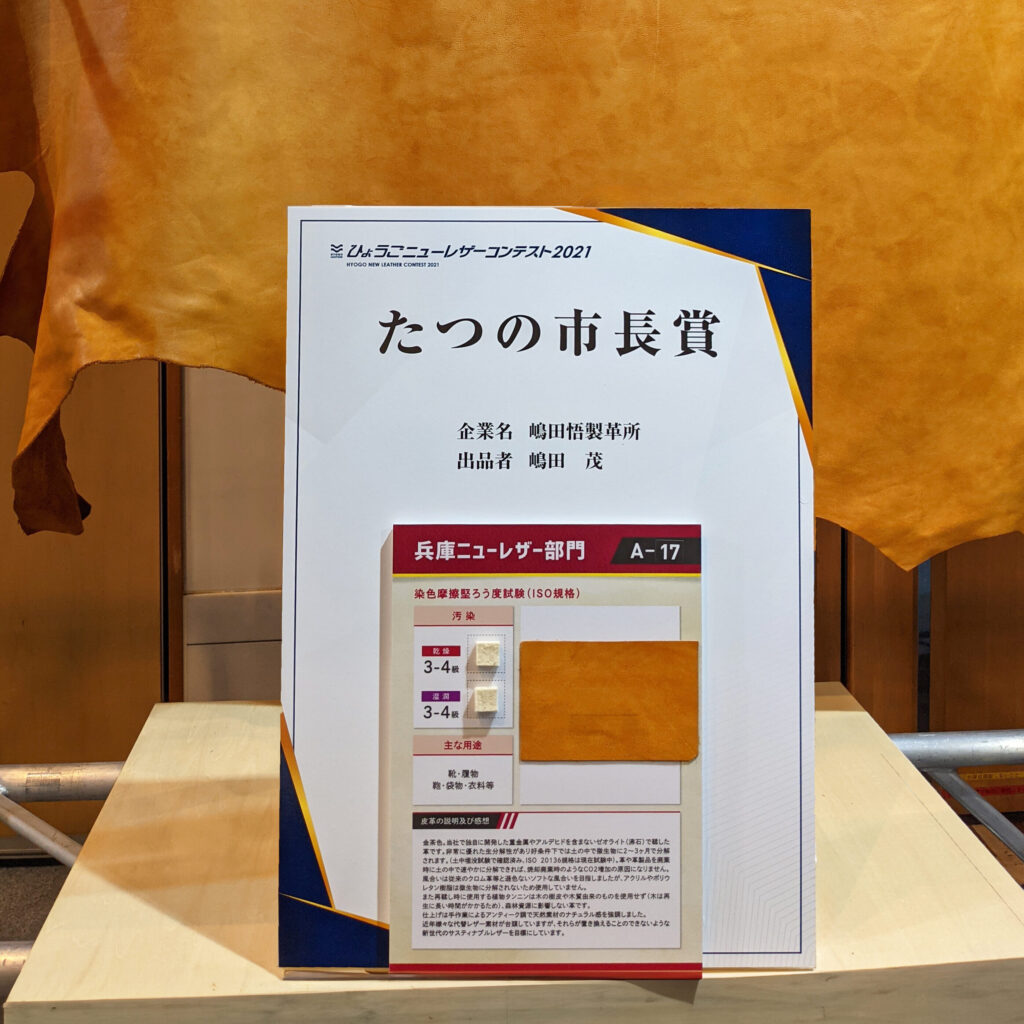

This innovative natural leather material has won prizes in the New Leather Contest and has been exhibited at the Tokyo Leather Fair and Japan Leather Awards.

A new generation of sustainable leather that returns to the earth

We select and use biodegradable chemicals when making leather so that it can be returned to the soil. Decomposition has been confirmed through our own soil burial test, and over 40% decomposition was tested in 26 days by a European inspection agency*2.

If leather and leather products can be quickly decomposed in the soil when disposed of, they will not cause an increase in CO2 as would be the case when disposed of by incineration.

We aimed for a soft texture that is comparable to conventional chrome leather, but we do not use acrylic resin or polyurethane resin, which are often used in regular leather, as they are not decomposed by microorganisms.

In addition, the vegetable tannin used during re-tanning does not use tree bark or wood-derived materials (because wood takes a long time to regenerate), so the leather does not affect forest resources.

The finish is hand-crafted with an antique look that emphasizes the natural feel of natural materials. In recent years, various alternative leather materials have emerged, but our goal is to create a new generation of sustainable leather that cannot be replaced.

- 1.“BIO-DEG LEATHERⓇ” is not only biodegradable, but also increases the proportion of bio-based materials in the leather, aiming to become the ultimate bio-based material that stands above alternative leathers.

- 2. ISO 20136 is an international standard for the degradability of natural leather by microorganisms, newly established in 2020.

ECO-ZEOLITE TANNINGⓇ

What is ECO-ZEOLITE TANNINGⓇ?

By using zeolite, a harmless mineral, as a tanning agent instead of traditional tanning materials (vegetable tannins and chromium), we can create BIO-DEG LEATHERⓇ*1, a leather that returns to the natural environment. When buried in soil under certain conditions, it decomposes in about six months and returns to the earth as nutrients.

This innovative natural leather material has won prizes in the New Leather Contest and has been exhibited at the Tokyo Leather Fair and Japan Leather Awards.

A new generation of sustainable leather that returns to the earth

We select and use biodegradable chemicals when making leather so that it can be returned to the soil. Decomposition has been confirmed through our own soil burial test, and over 40% decomposition was tested in 26 days by a European inspection agency*2.

If leather and leather products can be quickly decomposed in the soil when disposed of, they will not cause an increase in CO2 as would be the case when disposed of by incineration.

We aimed for a soft texture that is comparable to conventional chrome leather, but we do not use acrylic resin or polyurethane resin, which are often used in regular leather, as they are not decomposed by microorganisms.

In addition, the vegetable tannin used during re-tanning does not use tree bark or wood-derived materials (because wood takes a long time to regenerate), so the leather does not affect forest resources.

The finish is hand-crafted with an antique look that emphasizes the natural feel of natural materials. In recent years, various alternative leather materials have emerged, but our goal is to create a new generation of sustainable leather that cannot be replaced.

- 1.“BIO-DEG LEATHERⓇ” is not only biodegradable, but also increases the proportion of bio-based materials in the leather, aiming to become the ultimate bio-based material that stands above alternative leathers.

- 2. ISO 20136 is an international standard for the degradability of natural leather by microorganisms, newly established in 2020.

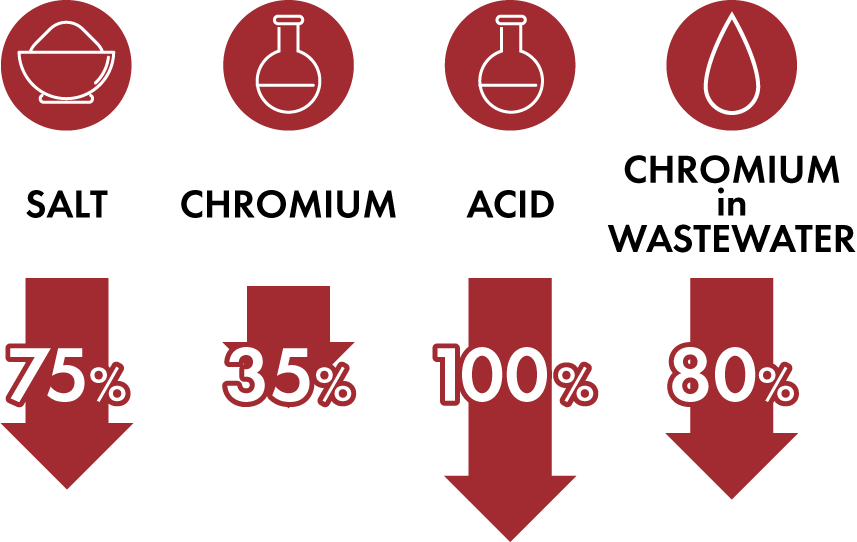

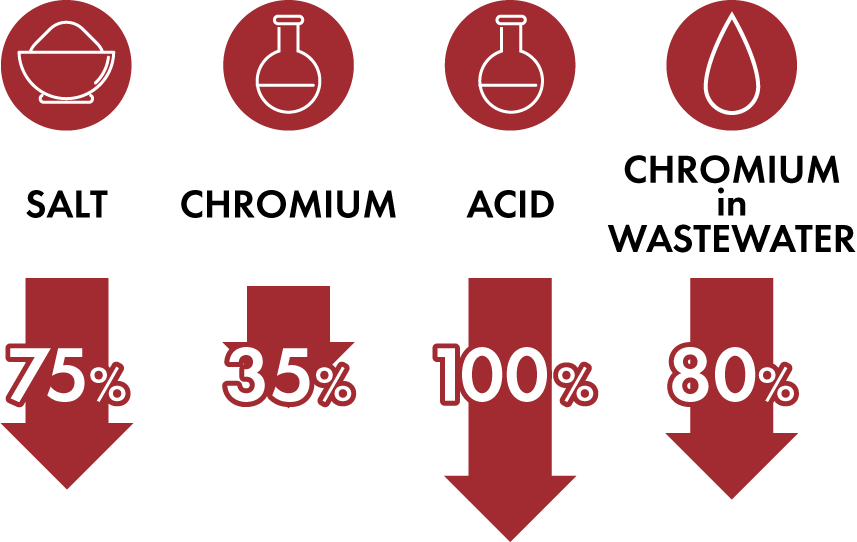

NSA Chrome Tanning

Innovative eco-friendly chrome tanning

The NSA chrome tanning method (Non Salt and Acid) is a cutting-edge chrome tanning technology that does not use salt or strong acids. We began working on it in 2022 and are conducting implementation tests on a production basis.

In the current pilot production, we are maintaining the quality and heat resistance of the leather as before.

- Amount of salt reduced by 70%

- 35% reduction in chrome tanning agent usage

- Amount of sulfuric acid: 100% reduction

- Amount of chromium oxide in wastewater reduced by more than 80%

We are achieving this by ensuring that chrome-tanned drainage water is transparent and reduces environmental impact.

NSA Chrome Tanning

Innovative eco-friendly chrome tanning

The NSA chrome tanning method (Non Salt and Acid) is a cutting-edge chrome tanning technology that does not use salt or strong acids. We began working on it in 2022 and are conducting implementation tests at production pace.

In the current pilot production, we are maintaining the quality and heat resistance of the leather as before.

- Amount of salt reduced by 70%

- 35% reduction in chrome tanning agent usage

- Amount of sulfuric acid: 100% reduction

- Amount of chromium oxide in wastewater reduced by more than 80%

We are achieving this by ensuring that chrome-tanned drainage water is transparent and reduces environmental impact.

Vegetable Tannin Tanning

Using a unique method, we can produce surprisingly soft vegetable tanned leather (tanned leather).

It features highly versatile soft leather.

Normally, tanned leather has the image of being hard, but our tanned leather has excellent softness and can be used for a wide range of purposes, including clothing leather.

Vegetable Tannin Tanning

Using a unique method, we can produce surprisingly soft vegetable tanned leather (tanned leather).

It features highly versatile soft leather.

Normally, tanned leather has the image of being hard, but our tanned leather has excellent softness and can be used for a wide range of purposes, including clothing leather.

TYPE OF HIDE

All our hides are domestically produced.

Everything from procurement to final processing is completed in Japan.

All our hides are domestically produced.

Everything from procurement to final processing is completed in Japan.

Domestic Raw Hide

Cowhide

- Vegetable tannin tanning

- ECO-ZEOLITE TANNINGⓇ

- Chrome Tanning

- Soft leather ( For Clothing, bags, wallets, shoe uppers )

Cowhide

- Vegetable tannin tanning

- ECO-ZEOLITE TANNINGⓇ

- Chrome Tanning

- Soft leather ( For Clothing, bags, wallets, shoe uppers )

Horse Leather

- Vegetable tannin tanning

- ECO-ZEOLITE TANNINGⓇ

- Chrome Tanning

- Soft leather ( For jackets, bags, small leather goods etc. )

Horse Leather

- Vegetable tannin tanning

- ECO-ZEOLITE TANNINGⓇ

- Chrome Tanning

- Soft leather ( For jackets, bags, small leather goods etc. )

Gibier Leather

This is a business that recycles the skins of animals exterminated as pests in Hokkaido into leather and used as apparel and armors.

This is a business that recycles the skins of animals exterminated as pests in Hokkaido into leather and used as apparel and armors.

Deer Leather

It is tanned from sika deer. We also use our own tanning technology to create a unique deerskin that stands out from regular deerskin.

It is the opposite of mass-produced leather, which requires all products to have the same uniform appearance.

Deer Leather

It is tanned from sika deer. We also use our own tanning technology to create a unique deerskin that stands out from regular deerskin.

It is the opposite of mass-produced leather, which requires all products to have the same uniform appearance.

Brown Bear Leather

This project recycles the hides of brown bears, which are exterminated as pests in Hokkaido, like sika deer, into leather and used as clothing and accessories.

Please contact us for orders as this is a highly rare material.

Brown Bear Leather

This project recycles the hides of brown bears, which are exterminated as pests in Hokkaido, like sika deer, into leather and used as clothing and accessories.

Please contact us for orders as this is a highly rare material.

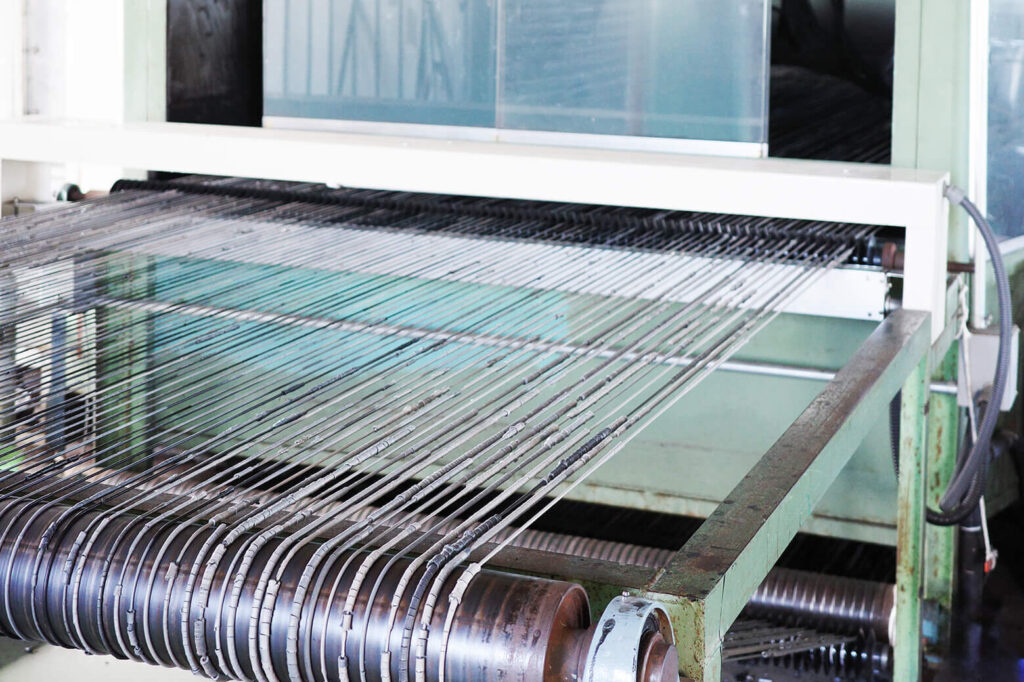

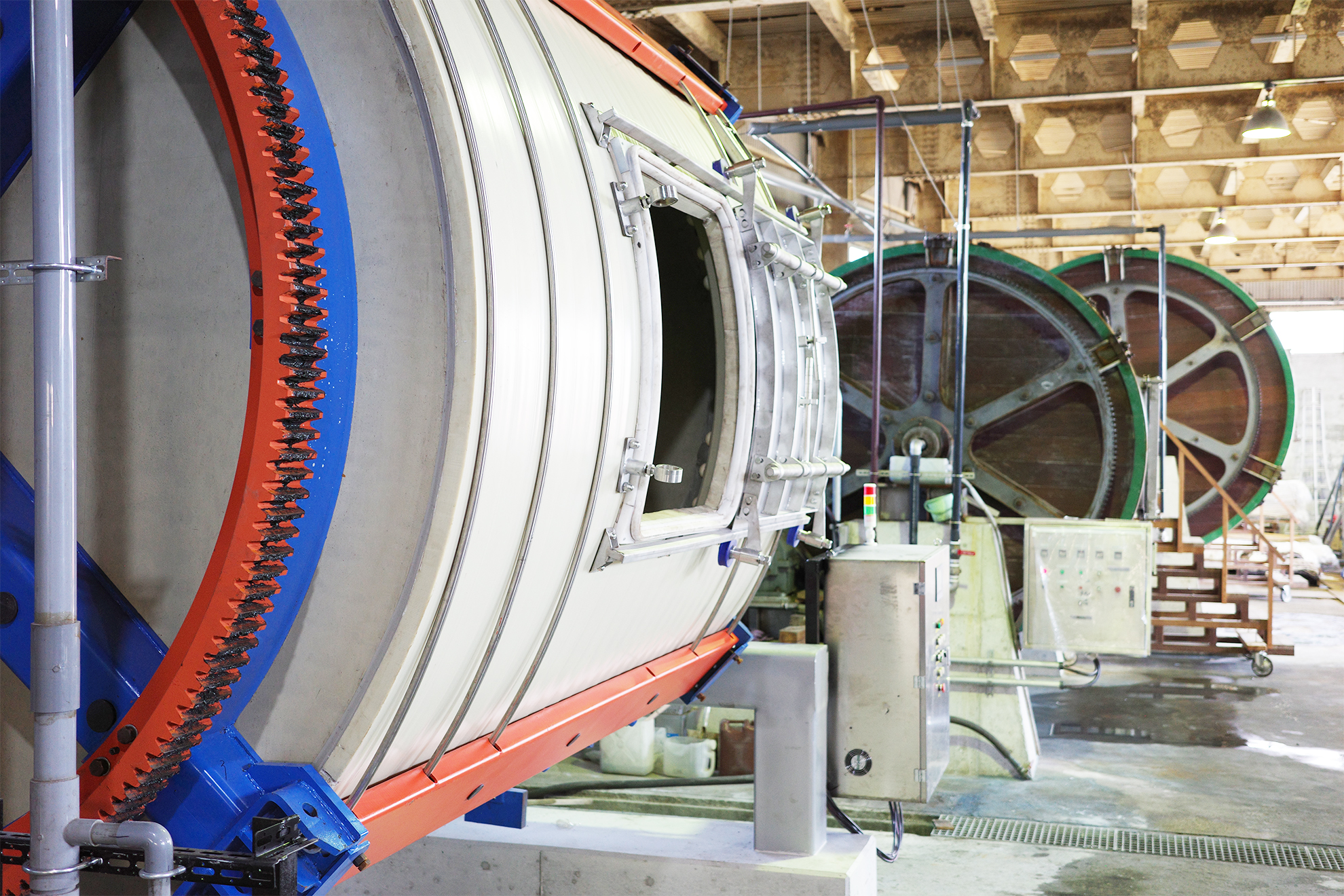

MACHINERY and EQUIPMENT

Our factory is equipped with the latest machinery and provides a safe and efficient working environment.

You can also take a tour of our factory and view our equipment during business meetings.

Our factory is equipped with the latest machinery and provides a safe and efficient working environment.

You can also take a tour of our factory and view our equipment during business meetings.